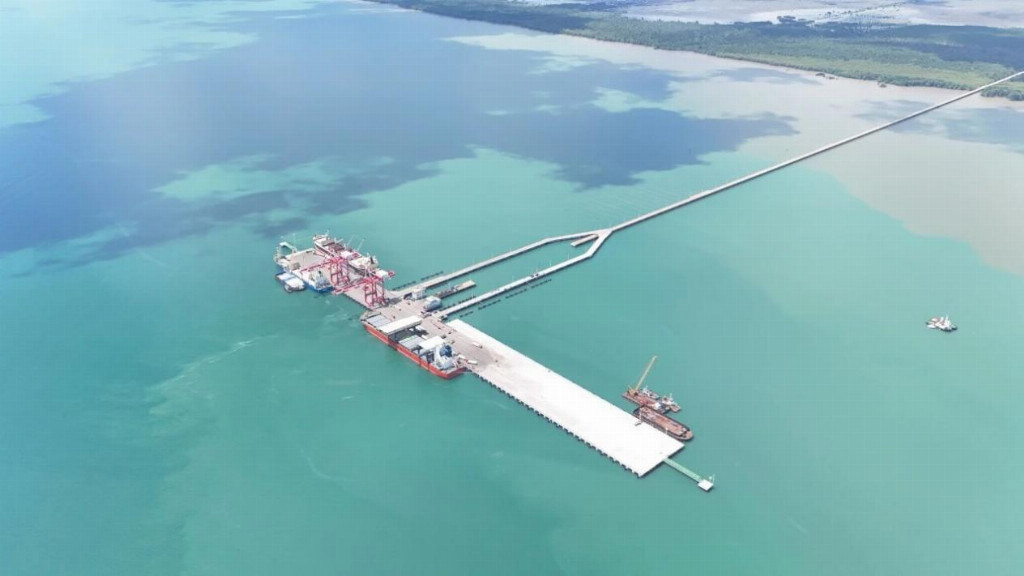

This project is located on Sumatra Island, Indonesia and is a key link in the pulp industry logistics chain of Jinguang Group. The main construction content of this expansion project includes the construction of a new pier with a length of 250 meters and a width of 70 meters, the expansion of an existing pier with a length of 128 meters and a width of 20 meters, and the demolition of the first phase steel bridge that has reached its service life and reconstruction according to the standards of a permanent approach bridge.

Since the project started on June 15, 2024, facing numerous challenges such as complex offshore construction environment, frequent rainy season impact, and long material transportation cycle, the project management team has scientifically organized and carefully constructed, and finally completed all construction tasks 10 days ahead of schedule, demonstrating excellent overseas engineering performance.

Traditional construction methods are limited by maritime transportation and lifting capabilities, resulting in low efficiency and long cycles. To solve the problem of offshore operations, the project team innovatively adopted a construction plan of "vertical pouring and horizontal pushing of ground pumps and pump pipes" based on the tidal changes in the offshore waters. The ground pumps were arranged in the already poured structural sections, and the concrete was transported to the work surface by laying vertical pump pipes, and then horizontally pushed for pouring, forming a flow operation, greatly improving construction efficiency, and successfully achieving large-scale and rapid pouring of the dock surface layer, laying a solid foundation for early completion.

In order to optimize the process and save costs, the project team built their own prefabrication plant and mixing plant. While strictly controlling the quality of components, they achieved seamless connection and parallel promotion between factory prefabrication and on-site construction, significantly improving overall construction efficiency. The prefabrication factory undertakes the prefabrication task of reinforced concrete components such as dock beams and slabs, using standardized molds and assembly line operations to ensure accurate component dimensions and clean appearance. The automation control system of the mixing plant can accurately measure and automatically adjust raw materials such as cement, aggregates, and additives, fundamentally ensuring the quality stability and reliable performance of concrete. Two self built factory stations not only effectively reduce the costs of raw material transportation and component procurement, but also achieve synchronous prefabrication and cast-in-place operations, greatly shortening the construction period through the dual line parallel mode.

During the peak construction period, 9 construction ships and 3 groups of heavy equipment were operating at the same time. Pile driving ships, crane ships, tower cranes, and truck pumps were used to construct the pile foundation, install components, and pour the surface layer in an orderly manner, and multiple processes were seamlessly connected. The optimized positioning and operation path of the ship's machinery have reduced equipment idle time, providing a solid guarantee for efficient performance.

The representative of the owner of Jinguang Pulp Mill said at the acceptance site, "The professionalism of the Chinese team is admirable. Not only did they deliver a high-quality dock ahead of schedule, but they also created conditions for us to start production as soon as possible." (Ye Jiale, Third Navigation Bureau)